Spring 2022

Term: Spring 2022

Professor: Marshall Prado

Team: Matthew Baumgartner, Cayden Masters, Trey Robbins

Awards:

EUReCA 2nd Place

Professor: Marshall Prado

Team: Matthew Baumgartner, Cayden Masters, Trey Robbins

Awards:

EUReCA 2nd Place

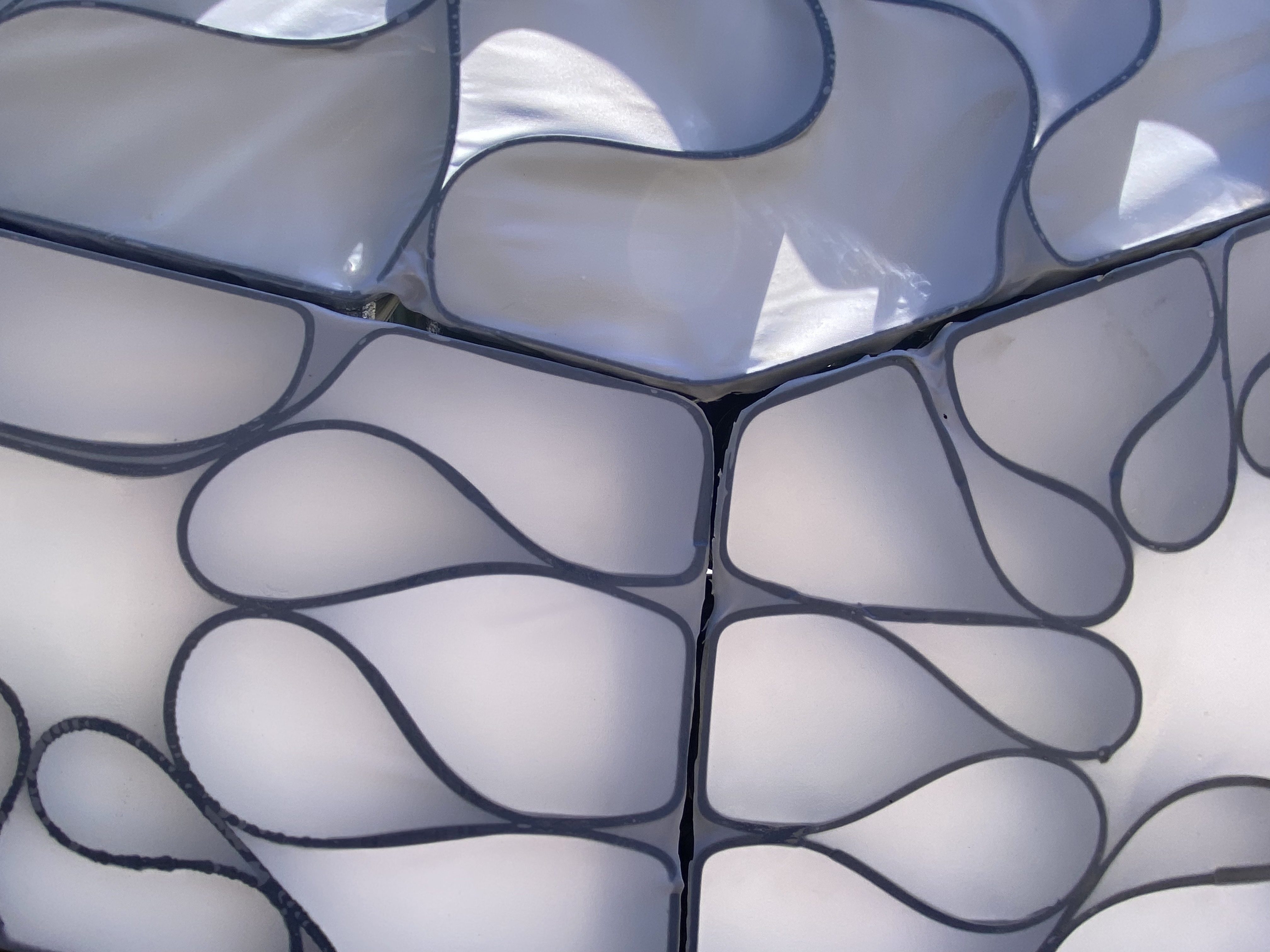

Traditional 3D-printing uses a planar workflow where the print bed and all subsequent print layers are flat and parallel. Early research investigations looked for ways that this planarity could be broken in order to take advantage of a multi-axis KUKA setup. Because the existing setups started with a flat (planar) print bed, the following investigations tested ways that prints could begin planar, but develop into non-planar surfaces. These prints had cleaner layer lines and quicker print time.

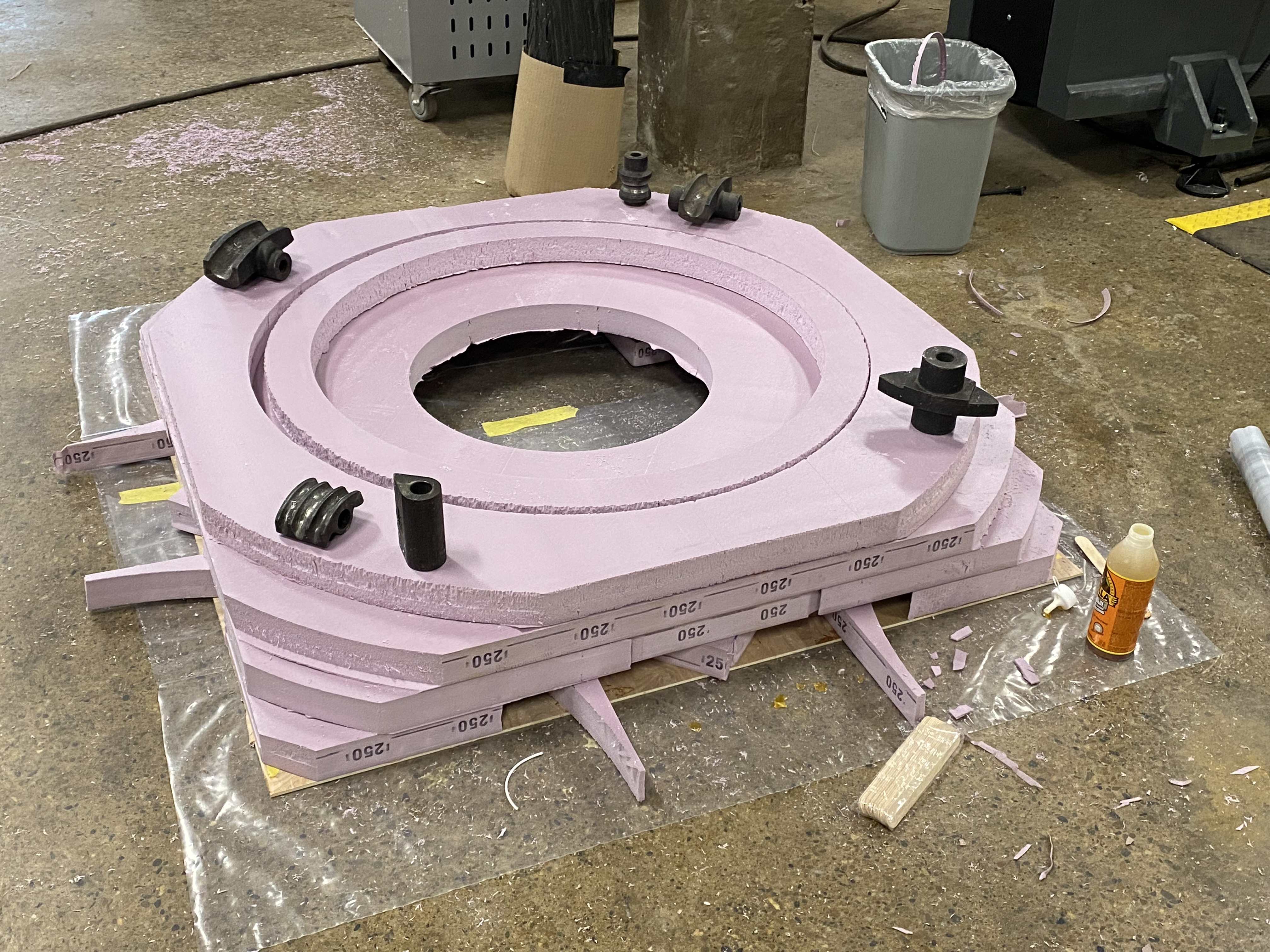

While this “planar to non-planar” workflow worked well in testing, it presented new issues when applyed to a larger component based geometry. Follow up investigations looked into creating a non-planar print surface which could serve as a universal mold for any number of components. This mold then could also function as a design constraint for both component and overall geometry.

While this “planar to non-planar” workflow worked well in testing, it presented new issues when applyed to a larger component based geometry. Follow up investigations looked into creating a non-planar print surface which could serve as a universal mold for any number of components. This mold then could also function as a design constraint for both component and overall geometry.